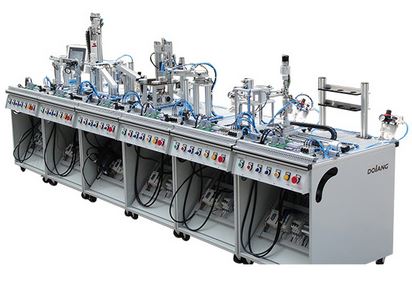

DLMPS-600B Modular flexible production system

The system consists of six stations: distribution unit, testing unit, processing unit, handling unit, assembly unit and classification storage unit, the main components of the system including: PLC, HMI, handling manipulator, switching power supply, hopper, sorting bin, workpiece pushing member, slide bar pushing member, punch motor assembly, detection cylinder assembly, translation stage, rotating table, cylinder, solenoid valve, DC gear motor, vacuum generator, various industrial sensors, a variety of commonly used detection typical switch, button.

The system software is controlled by MCGS industrial configuration monitoring software, through the software can monitor the operational status and operation process.

Technical parameters

Scope of Learning

- Total dimension : 3600×800×1420mm

- Input power : single-phase, three-wire AC 220V±10% 50Hz/60Hz

- Capacity : < 5KVA

- Computer, computer table

- PLC module

- Air compressor